We in the SAFe community love to tell the story of Toyota and how its development and implementation of Lean concepts manifested by the Toyota Production System gave Toyota a massive manufacturing advantage. We love presenting the House of Lean and wowing our clients with words like Kanban, Kaizen, Muda, and Gemba. We love coaching organizing around the value stream and delivering a flow of value. We love this because we see the real benefit Lean and Agile thinking brings to an enterprise. However, there is another valuable but lesser known Toyota story we should tell and and that is the harsh economic consequences of a “broken” value stream

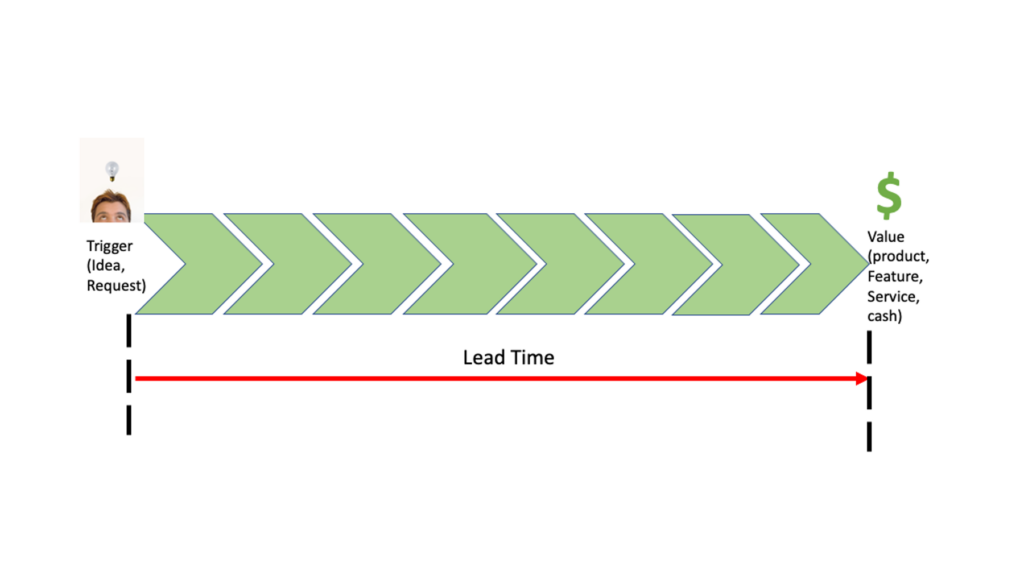

A value stream represents the series of steps for how we go from some trigger event to the delivery of value, or as we often like to say, “concept to cash”. Value stream thinking encourages us to take a systems view and optimize for delivery of outcomes rather than taking a more siloed view and optimizing for perceived local “efficiency”.

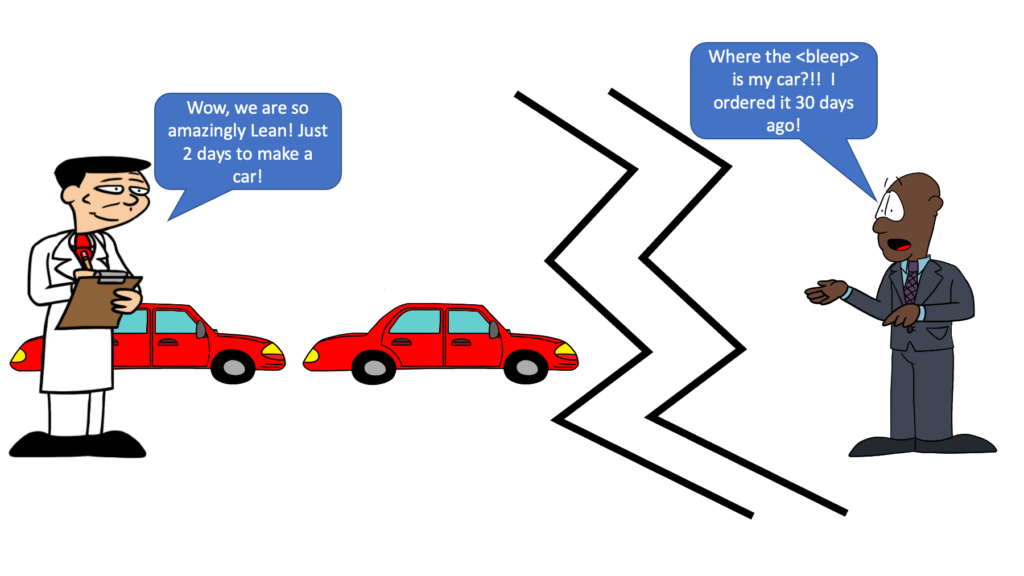

Mapping the value stream helped Toyota engineers learn where there were wasteful delays resulting and remove them. Taiichi Ohno’s dream was to minimize the time from when a customer ordered a car until when it was delivered.

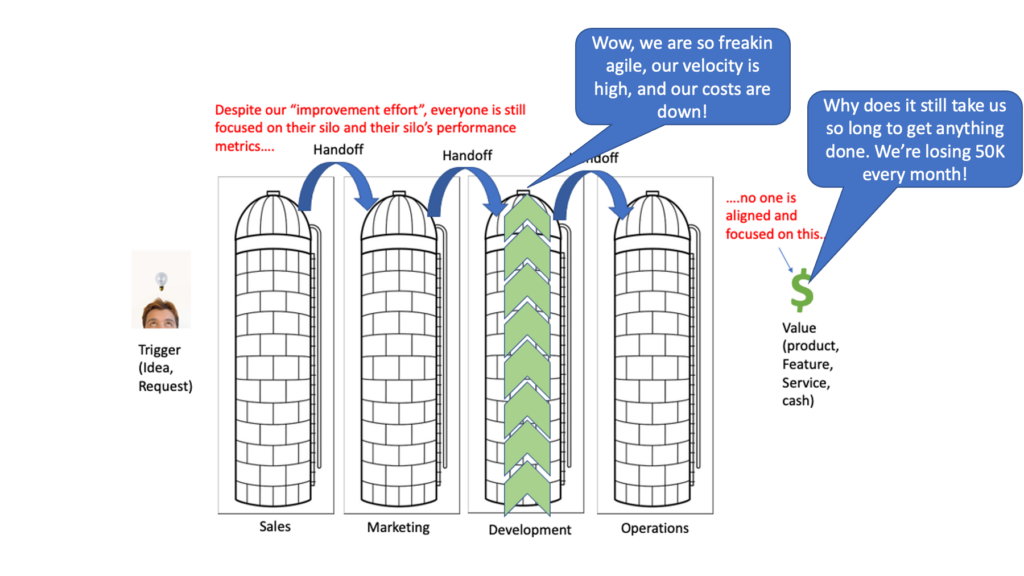

A broken value stream is when the flow of value is interrupted and delayed because organizational silos or practices artificially segment the value stream. Up until the mid 1980s Toyota was hampered by a broken value stream. In a situation we often find ourselves in, the cause of their value stream breakage was their artificial distinction between “business” and “technology”.

In their book “Competing Against Time” and also in an HBR article [Time- The Next Source of Competitive Advantage, HBR July 1988], George Stalk and Thomas Hout tell the story of Toyota’s “broken value stream” and how it effectively squandered their manufacturing gains. Until the 1980s Toyota was organized as the Toyota Motor Manufacturing Company which built cars and the Toyota Motor Sales Company which sold and distributed cars – technology and business. In the late 1970s the Toyota Motor Manufacturing company could manufacture a car is less than two days. However, the Toyota Motor Sales company’s entrenched bureaucratic organization squandered this gain taking nearly a month to process a sales order and deliver a vehicle. According to Stalk and Hout:

“Twenty to thirty percent of the cost of the car – more than it cost to actually manufacture the car – and more than 90% of the time the customer had to wait was consumed by the sales and distribution function” [Stalk and Hout, Competing against Time, pg. 68].

We can imagine the frustration this created for Taiichi Ohno where the whole point of the Toyota Product Systems was to “…reduce the time line from when the customer gives us an order to the point we can collect the cash”.

In 1982 the frustration boiled over and two companies were merged. The executives and directors of Toyota Motor Sales were replaced by executives and directors who trained in Lean thinking. New processes and management information systems supporting those processes were developed. By 1987 the sales cycle was reduced from a month to 6 days from order to delivery of the vehicle. The benefit of this time compression was far more than just a cost saving exercise. The ability to compress time in this manner gave Toyota a massive competitive advantage because they were able to go from “selling whatever was on the lot”, to “selling what the customer wanted”. The benefit of this is huge because the short cycle times meant Toyota was able to exploit fast learning cycles and discover what cars customers wanted. By reducing their timelines and embracing change they not only were able to turn over units more quickly, they could also command higher margins on their sales.

What is the lesson we should take from this lesser known Toyota story? Far too many digital transformations follow the pattern of Toyota’s broken value stream with the same results. While our clients obtain some economic gain from the ability of their technology teams to predictably create economic value we may not have really made a significant difference in our client’s ability to deliver value to their customer. Technology is only one part of the value stream just like Toyota Motor Manufacturing was only one part of Toyota’s vehicle delivery value stream. To deliver customer value Toyota had to receive an order for a car, manufacturing the car, and then deliver the car. Just manufacturing a car creates little value.

A common example of a “broken value stream” in software development is the hybrid agile implementation , often referred to as “agi-fall”, or waterscrumming used by many organizations. Even in organizations adopting SAFe to inform their way of working we see this pattern. The technology teams eagerly organize around the flow of value, but only within their silo.

While in this model we may be able to predictably create software in a very short period of time what have we gained if it takes a year or more to ideate, review, analyse, and fund a project before it is even seen by the technology organization? What have we gained if it takes several months to release software after its done?

In the Age of Software and Digital, just like Toyota, we risk squandering the gains of Lean-Agile adoption when our focus is only the technology side of the value stream or just a short segment of our value stream. To compete in the Agile of Software and Digital we need to learn Toyota’s lesson and not squander our technology gains. We need to remember Lean and Agile are not just IT or engineering science experiments. Rather as Toyota learned they are strategies for successfully competing in the time compressed era of the digital business.